This comprehensive manual provides detailed parts information for the Advance SC750, covering models like SC750-26D, SC750-28D, and SC750-28C, including ST variants, to help users identify and order parts efficiently.

1.1 Overview of the SC750 Model

The Advance SC750 is a high-performance, battery-powered walk-behind scrubber designed for efficient cleaning in commercial and industrial settings. It offers varying models, including the SC750-26D with a 26-inch cleaning path and the SC750-28D and SC750-28C with a 28-inch path. Known for its durability and reliability, the SC750 is built to handle demanding environments while maintaining high productivity. Its ergonomic design and advanced features make it a popular choice for facility maintenance professionals. This manual provides detailed insights into its components, ensuring users can maintain and repair their machines effectively.

1.2 Importance of the Parts Manual

The parts manual is essential for maintaining, repairing, and identifying components of the Advance SC750. It provides detailed diagrams, part numbers, and descriptions, ensuring accurate identification and ordering of replacement parts. This resource is crucial for prolonging machine lifespan, enhancing performance, and reducing downtime. By referencing the manual, users can troubleshoot issues, perform routine maintenance, and ensure compliance with manufacturer specifications. Whether for the SC750-26D, SC750-28D, or SC750-28C models, this guide is indispensable for operators and technicians, offering clear instructions to maintain efficiency and safety in daily operations.

1.3 Target Audience for the Manual

The Advance SC750 parts manual is designed for operators, maintenance personnel, and service technicians working with the SC750 models. It caters to professionals needing detailed parts information for repairs, maintenance, and component identification. The manual is also useful for facility managers overseeing equipment upkeep and for distributors or dealers requiring accurate part specifications. By providing clear, concise information, it ensures that all users can efficiently manage their machines, whether they are handling routine maintenance or troubleshooting specific issues.

Specific Models Covered in the Manual

The manual covers the SC750-26D, SC750-28D, and SC750-28C models, including ST variants, ensuring comprehensive parts information for each specific machine configuration and operational need.

2.1 SC750-26D Model Specifications

The SC750-26D model features a 26-inch cleaning path, designed for efficient floor coverage and maneuverability. This walk-behind scrubber is ideal for medium-sized areas, offering high productivity per tankful with up to 84 minutes of continuous operation. Its compact design allows for easy navigation in tight spaces while maintaining robust cleaning performance. The manual provides detailed specifications, including dimensional data, weight, and operational parameters, ensuring users can identify compatible parts and maintain optimal machine performance. This model is well-suited for commercial and industrial settings, requiring regular maintenance to uphold its efficiency and longevity.

2.2 SC750-28D and SC750-28C Models

The SC750-28D and SC750-28C models are distinguished by their 28-inch cleaning path, offering enhanced cleaning capacity compared to the SC750-26D. These models are designed for larger spaces, providing increased efficiency and productivity. Both variants share similar operational features but differ in specific configurations, such as brush sizes and optional accessories. The parts manual details their unique components, ensuring accurate part identification and ordering. These models are popular in industrial and commercial environments, where higher cleaning demands require reliable and durable equipment. Regular maintenance is crucial to sustain their performance and extend service life.

2.3 SC750 ST and SC800 ST Variants

The SC750 ST and SC800 ST variants are specialized walk-behind scrubbers designed for heavy-duty cleaning tasks. Both models share a 28-inch cleaning path and are battery-powered, offering high productivity with extended runtime. The SC750 ST is tailored for medium-sized areas, while the SC800 ST is optimized for larger spaces with advanced features. These variants are covered in the parts manual, ensuring users can identify and order specific components effortlessly. The manual highlights shared and unique parts between the two models, simplifying maintenance and repair processes. Regular upkeep is essential to maintain their performance and longevity in demanding environments.

Table of Contents

The manual includes sections on introduction, parts listing, maintenance, troubleshooting, and technical specifications, providing a clear guide for users to navigate and locate necessary information efficiently.

The manual begins with an introduction to the Advance SC750, highlighting its features and intended use. Safety guidelines are emphasized to ensure safe operation and maintenance, including proper protective equipment and pre-operation checks. Readers are advised to read the manual thoroughly before using the machine. Important safety precautions are outlined to prevent accidents and ensure compliance with industry standards. These guidelines are essential for operators and technicians to understand potential hazards and maintain a safe working environment. By adhering to these instructions, users can optimize machine performance while minimizing risks.

3.2 Parts Listing and Identification

The parts listing and identification section provides a detailed catalog of components for the Advance SC750, including model-specific parts for SC750-26D, SC750-28D, and SC750-28C variants. Users are guided to reference part numbers from the Ref. No. columns for accurate ordering. If the Ref. No. column is blank, instructions direct users to consult the Kit column to identify the appropriate kit. This section ensures users can quickly locate and identify necessary parts, facilitating efficient maintenance and repairs. Accurate part identification is crucial for ordering the correct components and ensuring machine performance.

3.3 Maintenance and Repair Procedures

This section outlines step-by-step procedures for maintaining and repairing the Advance SC750, ensuring optimal performance and longevity. It includes scheduled maintenance checklists, troubleshooting common mechanical issues, and guidelines for replacing wear parts. Detailed instructions cover battery maintenance, charging procedures, and routine inspections. Users are advised to refer to the parts listing for accurate component identification and to use OEM parts for reliability. The manual emphasizes adhering to safety guidelines and best practices to prevent damage and ensure operator safety. By following these procedures, users can extend the lifespan of their machine and maintain its efficiency. Links to relevant diagrams and specifications are provided for clarity.

3.4 Troubleshooting Common Issues

This section provides solutions for common issues encountered with the Advance SC750, such as malfunctioning vacuum motors, squeegee assembly problems, or battery performance issues. Detailed diagnostic steps guide users in identifying root causes, from clogged hoses to faulty electrical connections. Repair procedures are outlined with clear instructions, ensuring operators can address problems efficiently. The manual also includes a reference chart for error codes and troubleshooting flowcharts. Users are directed to relevant parts listings for replacement components. By following these guidelines, operators can resolve issues quickly, minimizing downtime and ensuring continuous productivity. Links to technical diagrams further assist in troubleshooting complex problems.

3.5 Technical Specifications and Diagrams

This section provides detailed technical specifications for the Advance SC750, including dimensional data, weight, and operational capabilities. Comprehensive diagrams illustrate key components, such as the wiring and hydraulic systems, aiding in parts identification and machine maintenance. Schematics for battery-powered models highlight electrical connections and motor configurations. Dimensional drawings ensure accurate measurements for repairs or upgrades. The manual also includes exploded views of assemblies, simplifying disassembly and reassembly processes. These resources empower users to understand and maintain their equipment effectively, ensuring optimal performance and longevity of the SC750 and its variants.

Ordering Parts

Use part numbers from the reference columns in the parts list. Specify the model and serial number when ordering. Record this information for future reference.

4.1 How to Use the Parts List Effectively

To effectively use the parts list, locate the component needed using the reference numbers. Cross-reference with the kit column if the Ref. No. is blank. Use the part numbers from the Ref. No. columns to ensure accuracy. Record the model and serial number of your machine for future orders. This systematic approach ensures quick identification and ordering of the correct parts for your Advance SC750 model, including SC750-26D, SC750-28D, and SC750-28C variants.

- Reference part numbers accurately.

- Check kit columns for component details.

- Record model and serial numbers for future use.

4.2 Steps to Order Replacement Parts

To order replacement parts for your Advance SC750, start by referencing the parts list in the manual. Identify the required part using the Ref. No. column. If the Ref. No. is blank, check the Kit column to find the appropriate kit. Specify the part number and machine model when placing your order. Ensure to provide the serial number for accuracy. Contact an authorized dealer or supplier to complete the purchase. Always follow the manufacturer’s guidelines to ensure the correct parts are ordered and installed. Proper documentation and double-checking details prevent errors in the ordering process.

- Identify the part using Ref. No. or Kit column.

- Provide part number and machine model.

- Include the serial number for accuracy.

- Contact an authorized dealer or supplier.

4.3 Recording Model and Serial Number Information

Accurately recording the model and serial number of your Advance SC750 is essential for ordering parts and ensuring compatibility. Locate the nameplate on your machine to find these details. Use the space provided in the manual or a separate document to note this information. Include the model number (e.g., SC750-26D) and the serial number for future reference. This practice prevents delays or errors when requesting parts. Always double-check the numbers for accuracy before placing an order. Proper documentation ensures smooth communication with suppliers and guarantees the correct parts are delivered for your specific machine.

- Locate the nameplate on the machine.

- Record the model and serial numbers accurately.

- Double-check for errors before ordering.

Machine Specifications

The Advance SC750 is a battery-powered, walk-behind scrubber designed for high productivity, featuring a 26-inch or 28-inch cleaning path and up to 84 minutes of runtime per charge.

5.1 Key Features of the SC750

The Advance SC750 is a high-performance, battery-powered walk-behind scrubber designed for efficient cleaning. It offers a robust design, intuitive controls, and a reliable operation. The machine features a large cleaning path, adjustable scrubbing pressure, and a spacious solution tank for extended cleaning sessions. Its ergonomic handle and quiet operation ensure operator comfort. The SC750 also supports eco-friendly cleaning practices with water conservation options. With models like the SC750-26D and SC750-28D, it caters to various cleaning needs, making it suitable for commercial and industrial environments. This machine is built to deliver consistent results and durability.

5.2 Dimensional and Weight Data

The Advance SC750 measures approximately 43 inches in length, 28 inches in width, and 41 inches in height, making it compact yet robust. It weighs around 380 pounds, ensuring stability during operation. The machine’s dimensions allow easy maneuverability in tight spaces. The SC750-26D and SC750-28D models have similar dimensions, with slight variations in weight due to different features. The SC750-28C model also aligns with these measurements, ensuring consistency across variants. These specifications are crucial for transportation, storage, and operational planning, providing users with clear expectations for handling the equipment effectively in various environments.

Maintenance and Repair

Regular maintenance and repair are crucial for the SC750’s longevity and performance. Inspect and replace wear parts as outlined to maintain efficiency and prevent breakdowns. Adhering to the manual’s guidelines ensures optimal functionality and extends the machine’s service life.

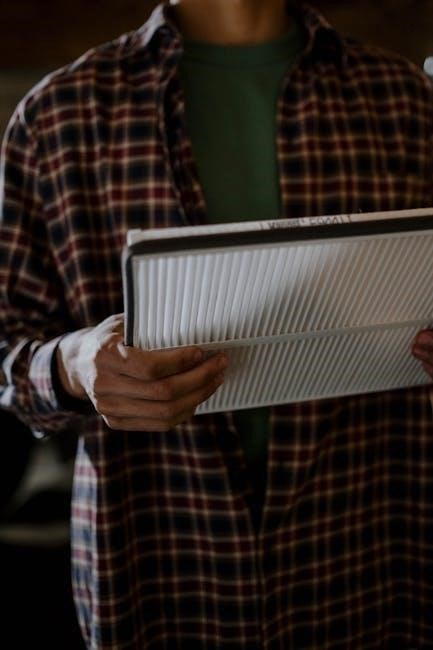

6.1 Scheduled Maintenance Checklist

The Advance SC750 requires regular maintenance to ensure optimal performance. Key tasks include inspecting the battery, checking and replacing brushes, and verifying squeegee condition. Operators should also check hydraulic fluid levels, inspect belts for wear, and clean filters. Schedule annual professional inspections for the vacuum motor. Refer to the manual for detailed intervals and procedures; Proactive maintenance prevents unexpected downtime and extends the machine’s lifespan. Always use OEM or compatible parts for replacements to maintain warranty and performance standards. Keep a maintenance log to track services and ensure compliance with manufacturer recommendations.

6.2 Troubleshooting Common Mechanical Issues

Common mechanical issues with the Advance SC750 include reduced cleaning efficiency, unusual noise, or operational stoppage. Start by checking for worn or misaligned brushes and squeegees. Ensure the recovery tank is not clogged and the battery is fully charged. Inspect the vacuum motor for worn brushes and replace them annually. If the machine vibrates excessively, check for imbalanced or loose components. Refer to the manual for diagnostic steps and repair procedures. Addressing issues promptly prevents further damage and ensures consistent performance. Always use genuine parts for repairs to maintain machine integrity and warranty compliance.

6.3 Replacement Guidelines for Wear Parts

Regularly inspect and replace wear parts like brushes, squeegees, and blades to maintain optimal performance. Brushes should be replaced every 50-100 hours or when showing uneven wear. Squeegees must be checked for cracks or wear and replaced to prevent water streaks. Blades on the recovery system should be inspected for damage and replaced as needed. Use only OEM or approved aftermarket parts to ensure compatibility and longevity. Refer to the parts manual for specific replacement intervals and procedures. Keeping spare wear parts on hand can minimize downtime and ensure continuous operation of your Advance SC750.

6.4 Battery Maintenance and Charging

Proper battery maintenance is crucial for extending the life of your Advance SC750. Charge the battery after every use, allowing it to cool before recharging. Avoid overcharging, as it can reduce battery longevity. Inspect terminals regularly for corrosion and clean them with a wire brush if necessary. For models with deep-cycle batteries, perform an equalization charge every 30 days. Always follow the manufacturer’s charging instructions and ensure the charger is compatible with your battery type. Neglecting these steps can lead to reduced performance and premature battery failure, requiring costly replacements. Refer to the manual for detailed charging procedures.

Service Manual as a Resource

The service manual is an essential resource for understanding machine operation, locating components, and troubleshooting issues, enabling technicians to perform effective maintenance and repairs efficiently.

7.1 Understanding Machine Operation

The service manual provides detailed insights into the operation of the Advance SC750, including explanations of key features, control panels, and operational modes. It outlines the machine’s design, functionality, and intended use, ensuring users understand how to utilize the equipment effectively. The manual also covers the roles of various components, such as brushes, squeegees, and motors, and explains how they contribute to the cleaning process. By understanding machine operation, technicians and operators can optimize performance, reduce wear and tear, and ensure safe, efficient use of the equipment for maintaining cleanliness in commercial and industrial environments.

7.2 Component Location and Identification

The manual includes detailed diagrams and descriptions to help users locate and identify components of the Advance SC750. Each part is labeled with reference numbers corresponding to the parts list, making it easier to find specific components. The manual covers key systems, such as brushes, motors, and squeegees, and provides visual guides for understanding their placement and function. This section ensures technicians and operators can quickly identify and access parts, streamlining maintenance and repair tasks. By referencing model-specific diagrams, users can accurately locate components unique to their machine, such as those in the SC750-26D, SC750-28D, or SC750-28C models.

Parts Availability

The Advance SC750 parts manual ensures easy availability of both OEM and aftermarket components, providing users with reliable options for maintenance and repairs through detailed parts listings.

8.1 OEM Replacement Parts

OEM (Original Equipment Manufacturer) replacement parts for the Advance SC750 are designed to meet exact specifications, ensuring optimal performance and compatibility. These parts are manufactured to maintain the machine’s original quality and reliability. The manual provides detailed listings for OEM components, including brushes, motors, and other essential items. Users can source these parts directly from authorized dealers or online retailers, ensuring genuine quality. The OEM parts are covered under warranty and are recommended for maintaining the machine’s longevity. Always refer to the parts manual for correct part numbers to avoid mismatches. This ensures seamless repairs and extended machine lifespan;

8.2 Aftermarket and Spare Parts Options

Aftermarket and spare parts for the Advance SC750 are widely available, offering cost-effective alternatives to OEM components. These parts are designed to meet or exceed original specifications, ensuring reliable performance. Online retailers, third-party suppliers, and equipment dealers provide a range of options, including brushes, squeegees, and motors. While aftermarket parts may not carry the OEM warranty, they often deliver significant savings without compromising quality. Users can cross-reference part numbers in the manual to ensure compatibility. Spare parts are ideal for maintaining machine uptime and are readily accessible through various suppliers, making repairs more affordable and efficient for owners and operators.

Safety and Operating Guidelines

This section outlines essential safety protocols and operating guidelines for the Advance SC750, crucial for ensuring safe, effective, and efficient proper machine operation and longevity.

9.1 Pre-Operational Checks

Before operating the Advance SC750, perform a thorough pre-operational inspection to ensure all components are in optimal condition. Check the battery terminals for cleanliness and secure connections, and verify the charge level. Inspect the squeegee and brushes for wear or damage, ensuring proper alignment and functionality. Examine the solution and recovery tanks for leaks or blockages. Test all safety features, such as emergency stops and alarms, to ensure they function correctly. Review the control panel for any error messages or alerts. Finally, confirm that all fluid levels, including cleaning solution and rinse water, are adequate for operation. Always refer to the manual for specific guidelines.

9.2 Safe Operating Practices

Always wear personal protective equipment, such as helmets, gloves, and safety glasses, when operating the Advance SC750. Ensure the area is clear of obstacles and bystanders. Operate the machine in well-ventilated spaces to avoid inhaling cleaning solution fumes. Use the scrubber only on approved surfaces and avoid steep inclines to prevent instability. Follow weight and load guidelines to maintain balance. Keep children and unauthorized individuals away from the machine. Familiarize yourself with controls and avoid sudden movements. Regularly inspect cables and connections to prevent electrical hazards. Properly handle batteries and electrical systems to avoid accidents. Follow all safety guidelines outlined in the manual for optimal operation.

Technical Diagrams and Schematics

Includes detailed component diagrams, wiring schematics, and hydraulic layouts for the SC750, ensuring technicians can locate and identify parts efficiently for maintenance and repairs.

10.1 Component Diagrams

The manual features detailed component diagrams that visually represent the SC750’s structure, making it easier to identify and locate parts. These diagrams include labeled illustrations of the machine’s major systems, such as the brush motors, solution tanks, and control panels. By referring to these diagrams, users can quickly understand the assembly and relationships between components, which is essential for effective maintenance and repair. The diagrams are cross-referenced with the parts list, ensuring accurate identification and ordering of replacement parts. This visual guide is an invaluable resource for technicians and operators alike, enhancing efficiency and reducing downtime.

10.2 Wiring and Hydraulic Schematics

The manual includes detailed wiring and hydraulic schematics to help users understand the machine’s electrical and hydraulic systems. These diagrams provide a clear view of circuit connections, hydraulic pathways, and component interactions. Technicians can use these schematics to diagnose electrical issues, trace hydraulic lines, and identify potential fault points. The wiring diagrams are color-coded for clarity, while hydraulic schematics highlight pressure points and flow directions. Cross-referenced with the parts list, these schematics ensure accurate identification of components, making repairs and maintenance more efficient. They are essential for troubleshooting and ensuring proper machine operation.

Cross-Compatibility of Parts

Parts for the SC750 are cross-compatible with select SC800 models, including ST variants, allowing shared components to reduce inventory needs for maintenance and repairs efficiently.

11.1 Interchangeability with SC800 Models

The SC750 parts are interchangeable with select SC800 models, including the ST variants, due to shared design features. This compatibility simplifies maintenance and reduces the need for multiple part inventories, ensuring cost and time efficiency for users maintaining both models. Key components like brush motors and squeegee assemblies can be used across both series, while specific parts like control panels may vary. Always verify part numbers from the manual before ordering to ensure proper fitment and functionality. This cross-compatibility is a strategic advantage for operators managing a fleet of SC750 and SC800 machines. Proper identification of compatible parts is essential for maintaining performance and longevity.

11.2 Shared Components Across Variants

Various components are shared across SC750 and SC800 variants, including brush motors, squeegee assemblies, and control panels, ensuring consistency and simplifying maintenance. However, certain parts like hydraulic systems and cleaning paths differ, requiring specific attention. Shared components reduce inventory needs and streamline repairs. Always refer to the manual for precise part compatibility to avoid mismatches. This design approach maximizes efficiency and cost-effectiveness for users managing multiple models. Proper identification ensures optimal performance and longevity of the equipment.

The Advance SC750 parts manual is an essential resource for maintaining and repairing your equipment. It provides detailed specifications, diagrams, and part identification. For further assistance, refer to official Nilfisk-Advance support channels or authorized dealers.

12.1 Summary of Key Information

The Advance SC750 parts manual is a critical resource for users, detailing specifications, maintenance, and repair procedures for models like SC750-26D, SC750-28D, and SC750-28C. It provides essential guidance on ordering parts, troubleshooting common issues, and understanding technical diagrams. The manual emphasizes scheduled maintenance, battery care, and safe operating practices to ensure longevity and efficiency. By referencing this guide, users can identify components, resolve mechanical problems, and maintain optimal performance. For additional support, users are directed to official Nilfisk-Advance resources and authorized dealers for genuine parts and expert assistance.

12.2 Additional Resources and Support

For further assistance, users can access additional resources, including OEM websites, authorized dealers, and online platforms offering genuine Advance parts. Technical support teams are available to address complex issues, while online forums and communities provide peer-to-peer advice. Official Nilfisk-Advance websites offer downloadable manuals, repair guides, and updated part listings. Users can also contact local distributors for personalized support. These resources ensure comprehensive assistance, helping users maintain and repair their SC750 models effectively. By leveraging these support channels, users can maximize their machine’s performance and lifespan with reliable, genuine components and expert guidance.