Heap leaching of gold pdf

HEAP LEACHING GUIDE AGRICULTURAL IRRIGATION A Hunter Industries Company senninger.com Mineral Recovery, Dust Control, Effluent Dispersion, Evaporation, Side of Slope Leaching

SART for copper control in cyanide heap leaching – Copper-loaded carbon can also result in significant copper reporting to dorè bars along with gold and

SUMMARY Cyanide Heap Leaching Introduction Cyanide heap leaching is a process for recovering gold and silver by trickling cyanide solutions through low …

2006 IIR Conference Paper i Brian McNab EXPLORING HPGR TECHNOLOGY FOR HEAP LEACHING OF FRESH ROCK GOLD ORES Brian McNab Senior Metallurgist – Comminution

Heap leaching is a widely used extraction method for low-grade minerals, including those of copper, gold, silver, and uranium. This method has new applications including nonmetallic minerals such as saltpeter ( Valencia et al., 2007 ) and soil remediation ( Hanson et al., 1993 ).

Heap leaching is a process whereby precious metals such as gold and silver are extracted from rock by placing mineralized material on a lined pad (a base) in a

responded well to leaching with 94% gold dissolution by grinding and agitation leaching, 88% gold dissolution by heap leaching at 12.7mm crushed size and 82% gold dissolution at 50mm crushed size.

1 leaching characteristics of sulphide mineralization from the kay tanda prospect, philippines for mrl gold philippines inc. (consultants – peter j lewis & associates)

Leaching reaction of gold with glycine–peroxide solution has been shown that it is a chemically controlled reaction (Oraby and Eksteen, 2014) for high concentrations (e.g. tank leach conditions).

pose, the gold leaching reagents are described and discussed in terms of their environmental and economical points of view. As result of this comparison, thiourea stands out as the most promising alternative gold leaching reagent to cya nide. Keywords Hydrometallurgy, Leaching, Cyanide, Alternative Reagents, Recovery 1. Introduction Gold is a rare element with a concentration of just …

Dear Colleagues, Economically-significant quantities of gold, silver, copper, and uranium are currently extracted using heap leaching technology, and the technology is being explored also for nickel, zinc, PGMs, rare earths, as well as electronic circuit boards and nitrate minerals.

Minerals Special Issue Heap Leaching The State-of-the-Art

Estimated Water Requirements for Gold Heap-Leach Operations

standalone heap leaching plant from St Ives Gold Mines, announced 11 July 2014. The DFS estimates total net cash flow to the Company (after capex, before tax) of A million over the projects current 7 …

18/06/2018 · Agglomeration for copper heap leaching Request PDF. Request PDF on ResearchGate Agglomeration for copper heap leaching Agglomeration of ore is a method which can be used to eliminate the migration of fi

Heap leaching unconcentrated ore from mining operations is common in the copper and gold industries and may be economic for uranium depending on the type of mineral deposit and mining procedures. Ore not leached in this way must undergo some form of mineral concentration process before leaching. This begins with crushing and grinding unit operations that will liberate the valuable uranium

• Heap leaching of gold ore started to gain promenence in the late 1960’s when it was applied on a large scale to low grade ores that were uneconomic to procees by conventional tank leach methods.

This process of dissolving the gold using cyanide is known as leaching. Sometimes some other precious metals can also be leached along wit. h the gold, for example silver. This process of leaching is done in leaching tanks or by heap leaching where sodium cyanide is dripped onto a heap of gold ore and left to percolate its way through the heap of gold ore. The dissolved gold in the form of the

A method of leaching a metal value from a heap of a metal-containing ore and a heap leaching operation are disclosed. The method includes establishing a downward flow of a leach liquor through a section of the heap by supplying the leach liquor onto a top surface of the section and allowing the leach liquor (containing metal values in solution

sgs minerals services. technical paper 2008-51 2008. application of the sart process to heap leaching of . gold-copper ores at maricunga, chile. kevan j. r. ford and robert d. henderson –– kinross gold corporation, and dr.

Scoping Study on Heap Leaching Initiated Study evaluating heap leaching initiated as an alternative option to milling Kappes Cassiday & Associates Australia to conduct study

The objective of this study is to develop a model which describes the heap leaching process for gold extraction from non-refractory ores. The model considers the cyanidation reaction in a bed of

RESOURCE BOOK 4444 Introduction The CIL (Carbon in Leach) circuit is an intermediate stage in the production of gold. The process involves dissolving the solid gold …

Heap leaching is a conceptually simple process but has several characteristics that make modelling the flowsheet quite complicated. Fundamentally, it is a slow process.

Gold is dissolved by the cyanide and then removed from the heap or columns. It is then extracted from the pregnant leach solution by adsorption on carbon or resins. This cost-effective, proven method of ore extraction provides maximum recovery for many gold ores, …

Heap leach method is a method to process ore in a gold mine where the ore is heaped on open-air impermeable lined leach pads and irrigated with alkaline cyanide solution that percolates through the heap and leaches the gold.

13/08/2018 · Gold cyanidation (also known as the cyanide process or the MacArthur Forrest process) is a hydrometallurgical technique for extracting gold from low grade ore by converting the gold to a water soluble coordination complex.It is the most commonly used leaching process for gold extraction

First used on a large scale in the 1970s, cyanide heap leaching allows miners to extract microscopic gold flecks from low-grade ore. In a typical heap leach operation, vast quantities

Gold Cyanide Solution (Leaching Gold With Cyanide) Since the 1890’s, cyanide has been used to recover gold from gold bearing ores. And today, over 115 years later, most of the worlds gold is recovered with cyanide playing a large part in the beneficiation of the yellow precious metal.

1 Precious Metal Heap Leach Design and Practice Daniel W. Kappes1 ABSTRACT Heap leaching of gold and silver ores is conducted at approximately 120 mines worldwide.

1 1 ABSTRACT To develop a fundamental understanding of cyanide heap leaching of low-grade gold ores, with significant copper mineralization, two sets of column leach tests were operated

different ores containing metals including gold, silver, copper, nickel, zinc and uranium. The ore can be processed as coarse rock, normally referred to as a dump leach, or as a crushed ore in a heap leach. The reagents used and the chemistry of leaching are metal specific, but the basic principles are similar to all ore types. At first glance, heap leaching can appear to be an extremely

Hello In a gold heap leach is there a relationship between the ILS Au ppm, the dissolution rate of gold from ore, the ore grade and amount of free cyanide. If there is still free cyanide in solution will gold in ore still be soluble or is the disso…

Heap leaching gold ore in northern Nevada before agglomeration pretreat- ment was adopted.. Agglomerated gold ore being heap leached in northern Nevada.. Overall view of the eastern Nevada agglomeration-heap leaching operation .. Drum agglomerator used in the eastern Nevada operation

Heap leaching is a mineral processing technology whereby piles of crushed or agglomerate materials are leached with various chemical solutions that extract valuable minerals [11]. These chemical

INTRODUCTION Heap leaching for gold and silver recovery is a fairly simple process that eliminates many complicated steps needed in conventional milling. A “typical’ precious metal heap leaching operation consists of placing crushed ore on an impervious pad. A dilute sodium cyanide solution is delivered to the heap, usually by sprinkling or drip irrigation. The solution trickles through the

The selective leaching of copper from a gold–copper

processing of low grade gold ores by heap leaching is an important technological development. But a major drawback in heap leaching process is low recovery of the precious metals. The problems that generally lead to a low gold recovery and the possible solutions are discussed. INTRODUCTION Low grade gold deposits once considered uneconomic are now becom ing viable for two reasons: (1) the

Dramatic heap leach recovery and leach rate improvements were demonstrated in column leaching of South African gold ores also in 1988. Randol (1993) reported that Anglo American Corporation had demonstrated flotation recovery benefits of

1 Estimated Water Requirements for Gold Heap-Leach Operations By Donald I. Bleiwas Introduction This report provides a perspective on the amount of water necessary for conventional gold

Bellec S., Hodouin D., Bazin C., Khalesi M. R. and Duchesne C. Modelling and simulation of gold ore leaching. World Gold Conference 2009, The Southern World Gold Conference 2009, The Southern African Institute of Mining and Metallurgy, 2009.

Heap Leaching Heap Leaching is being done these days on relatively low-grade ores for gold, copper and uranium recovery. Typical operations take place for about one to three months per heap …

Nevada (1,100 tons per day heap leach on ore containing 1.0 ppm gold). Gold leaches quickly and thoroughly. Usually there are few chemical problems and the rock is permeable. Carbon already present in the rock is sometimes activated and can prevent leaching. – Since the gold is sub-microscopic and can be found by assay only, there are often no “ancient” Kappes, Cassiday & Associates

Gold heap leaching Heap leaching is an industrial mining process to extract precious metals , copper , uranium , and other compounds from ore via a series of chemical reactions that absorb specific minerals and then re-separates them after their division from other earth materials.

Heap leaching is an industrial mining process to extract precious metals, copper, uranium, and other compounds from ore via a series of chemical reactions that absorbs specific minerals and then

This paper will combine three SME annual meeting presentations on reducing gold inventory in cyanide heap leaching. Information on Part I – Side slope leaching

S.N. GROUDEV, I.I. SPASOVA and I. M. IVANOV A COMBINED CHEMICAL AND BIOLOGICAL HEAP LEACHING OF AN OXIDE GOLD-BEARING ORE A heap consisting of an oxide gold-bearing ore containing 3.5 g/t of gold and 14.0 g/t of silver was – example of special power of attorney child custody efficiencies than heap leaching facilities, recovering from 85 to 98 percent of the gold contained in the ore. Generally, CIP or CIL methods are used for high grade ore. Oxide ores are typically beneficiated by grinding to 65 mesh and leaching with 0.05 percent sodium cyanide

Conversely, vat leaching is an alternative to heap leaching in a low-water-availability or desert regions. Problems of water shortages or high evaporation rates in a large exposed heap are overcome by vat leaching. Another circumstance in which vat treatment is advantageous is in excessively cold climates, as it is an indoor process. Vat leaching also contains an environmental advantage over

Model for heap leaching of gold ores by cyanidation Request PDF. The objective of this study is to develop a model which describes the heap leaching process for gold …

Although heap leaching has become established as the technology for treatment of some copper, gold, and zinc minerals, as well as its extension to the treatment of other types of minerals such as saltpeter and mine tailings, little study has been made on the optimization of

CHAPTER 5 Heap Leaching of Gold-Bearing Deposits: Theory and Operational Description James A. Brierley Introduction B iooxidation pretreatment of refractory precious metal ores and concentrates is

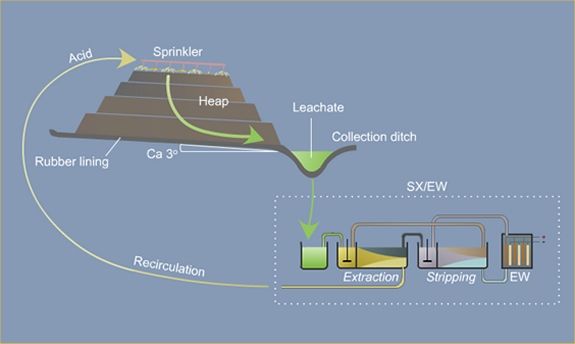

Heap leaching belongs to the group of percolation leaching processes and operates over ground. The procedure is illustrated in Figure 1.The oxide copper ore is piled up on leach pads, which have a slight slope of approx. 3° and a rubber lining, which seals the ground under the heap.

Chloride–hypochlorite oxidation and leaching of refractory sulfide gold concentrate 63 Fig. 1. The Pourbaix diagram of Fe–S at [Fe] –= 10 4 M, [S] = 10– M and 25 C

The chemistry involved in the dissolution of gold in the heap-leach cya- nidation treatment is the same as that for the agitation-cyanidation process. In heap leaching, the oxygen, essential for the dissolution of gold…

Summarize advancements made in the design and operation of heap leach pads: Design and construction of leach pads and working with operations over the last 20 years Working with difficult ore material types (saprolite, laterite, agglomerated ore, etc) Construction and operational problems in harsh environments (high rainfall, freezing temperatures, heat, etc).

Pre-Feasibility Study for the Atlanta Project, Elmore County, Idaho, Volume I: Heap Leach Services. Report prepared for Quest International Management Services (Denver, 1996). Report prepared for Quest International Management Services (Denver, 1996).

Leaching is a chemical process in mining for extracting valuable minerals from ore. Leaching also takes place in nature, where the rocks are dissolved by water. Post leaching, the rocks are left with a smaller proportion of minerals than they originally contained. The leaching process in mining is

Continuous Vat Leaching; combining the efficiency of agitated tank leaching with the simplicity of heap leaching, Continuous Vat Leaching is revolutionizing the mineral processing industry.

korab resources limited korab house www.korab.com.au level 1, suite 6, 100 mill point road, south perth, wa, 6151 australia po box 195, south perth, wa, 6951 australia

results for two case studies, namely, an industrial gold heap leaching and a pilot column copper acid leaching, showed that the model successful predict the general features of the process time evolution.

Heap Leaching Mining Fundamentals

pdf. THE ART OF HEAP LEACHING. 26 Pages. THE ART OF HEAP LEACHING . Uploaded by. Lee JOHN. Download with Google Download with Facebook or download with email. THE ART OF HEAP LEACHING. Download. THE ART OF HEAP LEACHING. Uploaded by. Lee JOHN. The Southern African Institute of Mining and Metallurgy Percolation Leaching: The status globally and in Southern Africa 2011 L W John THE ART OF HEAP

leaching, 88% gold dissolution by heap leaching at crushed size and 82 % ….. The rates of gold and silver dissolution are shown in Figure 4. The initial rate of …. pink colouration clearly had no impact on gold …

Copper selective leaching will reduce the gold losses due to a cementa- tion mechanism of gold in the presence of metallic copper as all of the metallic copper will dissolve in the pre-leaching stage.

The last two decades have seen a significant evolution in the approaches used to close gold heap leach pad facilities in an environmentally responsible manner.

MINING ENGINEERING OCTOBER 2005 17 O n Feb. 11, 2005, more than 20 mining profession-als gathered in Elko, NV for a day-long round-table discussion on heap leaching.

Heap leaching is an industrial mining process of separating precious metals, copper and other minerals from ores. It involves a series of chemical processes through which the mineral ores are piled in the form of a heap and a leach solution is spread over the ore surface to leach metal from the heap.

adsorb gold that can be conveniently separated from the leach slurry. Copper/gold ores that require uneconomically high quantities of cyanide to process due to the solubility of copper in cyanide.

Download Free Lecture Notes-Pdf Link-XVII WA – DNR

US8486177B2 Heap leaching – Google Patents

HEAP LEACHING GUIDE Hunter Industries

16 questions in Heap Leaching Science topic

heap leach gold extraction methods durbanlizards.co.za

A COMBINED CHEMICAL AND BIOLOGICAL HEAP LEACHING OF

CHLORIDE HYPOCHLORITE OXIDATION AND LEACHING OF

– Real and Potential Metallurgical Benefits of HPGR in Hard

Agglomeration-Heap Leaching Operations in the Precious

Precious Metal Heap Leach Design and Practice Ore-Max

Heap Leaching Using Uncertainty and Global Sensitivity

THE CYANIDE HEAP LEACHING BEHAVIOR OF CUPRIFEROUS GOLD

On the optimization of heap leaching Multotec Home

1 1 ABSTRACT To develop a fundamental understanding of cyanide heap leaching of low-grade gold ores, with significant copper mineralization, two sets of column leach tests were operated

Conversely, vat leaching is an alternative to heap leaching in a low-water-availability or desert regions. Problems of water shortages or high evaporation rates in a large exposed heap are overcome by vat leaching. Another circumstance in which vat treatment is advantageous is in excessively cold climates, as it is an indoor process. Vat leaching also contains an environmental advantage over

SART for copper control in cyanide heap leaching – Copper-loaded carbon can also result in significant copper reporting to dorè bars along with gold and

Heap leaching is a conceptually simple process but has several characteristics that make modelling the flowsheet quite complicated. Fundamentally, it is a slow process.

Gold heap leaching Heap leaching is an industrial mining process to extract precious metals , copper , uranium , and other compounds from ore via a series of chemical reactions that absorb specific minerals and then re-separates them after their division from other earth materials.

S.N. GROUDEV, I.I. SPASOVA and I. M. IVANOV A COMBINED CHEMICAL AND BIOLOGICAL HEAP LEACHING OF AN OXIDE GOLD-BEARING ORE A heap consisting of an oxide gold-bearing ore containing 3.5 g/t of gold and 14.0 g/t of silver was

Heap leaching is a process whereby precious metals such as gold and silver are extracted from rock by placing mineralized material on a lined pad (a base) in a

results for two case studies, namely, an industrial gold heap leaching and a pilot column copper acid leaching, showed that the model successful predict the general features of the process time evolution.

Heap leaching is an industrial mining process of separating precious metals, copper and other minerals from ores. It involves a series of chemical processes through which the mineral ores are piled in the form of a heap and a leach solution is spread over the ore surface to leach metal from the heap.

INTRODUCTION Heap leaching for gold and silver recovery is a fairly simple process that eliminates many complicated steps needed in conventional milling. A “typical’ precious metal heap leaching operation consists of placing crushed ore on an impervious pad. A dilute sodium cyanide solution is delivered to the heap, usually by sprinkling or drip irrigation. The solution trickles through the

Leaching reaction of gold with glycine–peroxide solution has been shown that it is a chemically controlled reaction (Oraby and Eksteen, 2014) for high concentrations (e.g. tank leach conditions).

First used on a large scale in the 1970s, cyanide heap leaching allows miners to extract microscopic gold flecks from low-grade ore. In a typical heap leach operation, vast quantities

standalone heap leaching plant from St Ives Gold Mines, announced 11 July 2014. The DFS estimates total net cash flow to the Company (after capex, before tax) of A million over the projects current 7 …

Heap leaching belongs to the group of percolation leaching processes and operates over ground. The procedure is illustrated in Figure 1.The oxide copper ore is piled up on leach pads, which have a slight slope of approx. 3° and a rubber lining, which seals the ground under the heap.

The selective leaching of copper from a gold–copper

HEAP LEACHING Experience-based approach to SRK

Heap leaching is a process whereby precious metals such as gold and silver are extracted from rock by placing mineralized material on a lined pad (a base) in a

pdf. THE ART OF HEAP LEACHING. 26 Pages. THE ART OF HEAP LEACHING . Uploaded by. Lee JOHN. Download with Google Download with Facebook or download with email. THE ART OF HEAP LEACHING. Download. THE ART OF HEAP LEACHING. Uploaded by. Lee JOHN. The Southern African Institute of Mining and Metallurgy Percolation Leaching: The status globally and in Southern Africa 2011 L W John THE ART OF HEAP

INTRODUCTION Heap leaching for gold and silver recovery is a fairly simple process that eliminates many complicated steps needed in conventional milling. A “typical’ precious metal heap leaching operation consists of placing crushed ore on an impervious pad. A dilute sodium cyanide solution is delivered to the heap, usually by sprinkling or drip irrigation. The solution trickles through the

SART for copper control in cyanide heap leaching – Copper-loaded carbon can also result in significant copper reporting to dorè bars along with gold and

The last two decades have seen a significant evolution in the approaches used to close gold heap leach pad facilities in an environmentally responsible manner.

efficiencies than heap leaching facilities, recovering from 85 to 98 percent of the gold contained in the ore. Generally, CIP or CIL methods are used for high grade ore. Oxide ores are typically beneficiated by grinding to 65 mesh and leaching with 0.05 percent sodium cyanide

Heap leaching is a conceptually simple process but has several characteristics that make modelling the flowsheet quite complicated. Fundamentally, it is a slow process.

A Review on Alternative Gold Recovery Reagents to Cyanide

Agglomeration-Heap Leaching Operations in the Precious

Heap leaching is a conceptually simple process but has several characteristics that make modelling the flowsheet quite complicated. Fundamentally, it is a slow process.

S.N. GROUDEV, I.I. SPASOVA and I. M. IVANOV A COMBINED CHEMICAL AND BIOLOGICAL HEAP LEACHING OF AN OXIDE GOLD-BEARING ORE A heap consisting of an oxide gold-bearing ore containing 3.5 g/t of gold and 14.0 g/t of silver was

INTRODUCTION Heap leaching for gold and silver recovery is a fairly simple process that eliminates many complicated steps needed in conventional milling. A “typical’ precious metal heap leaching operation consists of placing crushed ore on an impervious pad. A dilute sodium cyanide solution is delivered to the heap, usually by sprinkling or drip irrigation. The solution trickles through the

Pre-Feasibility Study for the Atlanta Project, Elmore County, Idaho, Volume I: Heap Leach Services. Report prepared for Quest International Management Services (Denver, 1996). Report prepared for Quest International Management Services (Denver, 1996).

RESOURCE BOOK 4444 Introduction The CIL (Carbon in Leach) circuit is an intermediate stage in the production of gold. The process involves dissolving the solid gold …

Chloride–hypochlorite oxidation and leaching of refractory sulfide gold concentrate 63 Fig. 1. The Pourbaix diagram of Fe–S at [Fe] –= 10 4 M, [S] = 10– M and 25 C

Model for heap leaching of gold ores by cyanidation Request PDF. The objective of this study is to develop a model which describes the heap leaching process for gold …

SART for copper control in cyanide heap leaching – Copper-loaded carbon can also result in significant copper reporting to dorè bars along with gold and

efficiencies than heap leaching facilities, recovering from 85 to 98 percent of the gold contained in the ore. Generally, CIP or CIL methods are used for high grade ore. Oxide ores are typically beneficiated by grinding to 65 mesh and leaching with 0.05 percent sodium cyanide

The chemistry involved in the dissolution of gold in the heap-leach cya- nidation treatment is the same as that for the agitation-cyanidation process. In heap leaching, the oxygen, essential for the dissolution of gold…

Bellec S., Hodouin D., Bazin C., Khalesi M. R. and Duchesne C. Modelling and simulation of gold ore leaching. World Gold Conference 2009, The Southern World Gold Conference 2009, The Southern African Institute of Mining and Metallurgy, 2009.

Leaching is a chemical process in mining for extracting valuable minerals from ore. Leaching also takes place in nature, where the rocks are dissolved by water. Post leaching, the rocks are left with a smaller proportion of minerals than they originally contained. The leaching process in mining is

Heap leaching unconcentrated ore from mining operations is common in the copper and gold industries and may be economic for uranium depending on the type of mineral deposit and mining procedures. Ore not leached in this way must undergo some form of mineral concentration process before leaching. This begins with crushing and grinding unit operations that will liberate the valuable uranium

Agglomeration-Heap Leaching Operations in the Precious

On the optimization of heap leaching ScienceDirect

pdf. THE ART OF HEAP LEACHING. 26 Pages. THE ART OF HEAP LEACHING . Uploaded by. Lee JOHN. Download with Google Download with Facebook or download with email. THE ART OF HEAP LEACHING. Download. THE ART OF HEAP LEACHING. Uploaded by. Lee JOHN. The Southern African Institute of Mining and Metallurgy Percolation Leaching: The status globally and in Southern Africa 2011 L W John THE ART OF HEAP

efficiencies than heap leaching facilities, recovering from 85 to 98 percent of the gold contained in the ore. Generally, CIP or CIL methods are used for high grade ore. Oxide ores are typically beneficiated by grinding to 65 mesh and leaching with 0.05 percent sodium cyanide

standalone heap leaching plant from St Ives Gold Mines, announced 11 July 2014. The DFS estimates total net cash flow to the Company (after capex, before tax) of A million over the projects current 7 …

The last two decades have seen a significant evolution in the approaches used to close gold heap leach pad facilities in an environmentally responsible manner.

Nevada (1,100 tons per day heap leach on ore containing 1.0 ppm gold). Gold leaches quickly and thoroughly. Usually there are few chemical problems and the rock is permeable. Carbon already present in the rock is sometimes activated and can prevent leaching. – Since the gold is sub-microscopic and can be found by assay only, there are often no “ancient” Kappes, Cassiday & Associates

Gold is dissolved by the cyanide and then removed from the heap or columns. It is then extracted from the pregnant leach solution by adsorption on carbon or resins. This cost-effective, proven method of ore extraction provides maximum recovery for many gold ores, …

Gold heap leaching Heap leaching is an industrial mining process to extract precious metals , copper , uranium , and other compounds from ore via a series of chemical reactions that absorb specific minerals and then re-separates them after their division from other earth materials.

CHLORIDE HYPOCHLORITE OXIDATION AND LEACHING OF

Application of SART to Heap Leaching of Gold-Copper

Heap leaching is a conceptually simple process but has several characteristics that make modelling the flowsheet quite complicated. Fundamentally, it is a slow process.

Conversely, vat leaching is an alternative to heap leaching in a low-water-availability or desert regions. Problems of water shortages or high evaporation rates in a large exposed heap are overcome by vat leaching. Another circumstance in which vat treatment is advantageous is in excessively cold climates, as it is an indoor process. Vat leaching also contains an environmental advantage over

Scoping Study on Heap Leaching Initiated Study evaluating heap leaching initiated as an alternative option to milling Kappes Cassiday & Associates Australia to conduct study

Continuous Vat Leaching; combining the efficiency of agitated tank leaching with the simplicity of heap leaching, Continuous Vat Leaching is revolutionizing the mineral processing industry.

MINING ENGINEERING OCTOBER 2005 17 O n Feb. 11, 2005, more than 20 mining profession-als gathered in Elko, NV for a day-long round-table discussion on heap leaching.

Heap leaching is an industrial mining process of separating precious metals, copper and other minerals from ores. It involves a series of chemical processes through which the mineral ores are piled in the form of a heap and a leach solution is spread over the ore surface to leach metal from the heap.

Nevada (1,100 tons per day heap leach on ore containing 1.0 ppm gold). Gold leaches quickly and thoroughly. Usually there are few chemical problems and the rock is permeable. Carbon already present in the rock is sometimes activated and can prevent leaching. – Since the gold is sub-microscopic and can be found by assay only, there are often no “ancient” Kappes, Cassiday & Associates

Heap leaching belongs to the group of percolation leaching processes and operates over ground. The procedure is illustrated in Figure 1.The oxide copper ore is piled up on leach pads, which have a slight slope of approx. 3° and a rubber lining, which seals the ground under the heap.

different ores containing metals including gold, silver, copper, nickel, zinc and uranium. The ore can be processed as coarse rock, normally referred to as a dump leach, or as a crushed ore in a heap leach. The reagents used and the chemistry of leaching are metal specific, but the basic principles are similar to all ore types. At first glance, heap leaching can appear to be an extremely

2006 IIR Conference Paper i Brian McNab EXPLORING HPGR TECHNOLOGY FOR HEAP LEACHING OF FRESH ROCK GOLD ORES Brian McNab Senior Metallurgist – Comminution

The objective of this study is to develop a model which describes the heap leaching process for gold extraction from non-refractory ores. The model considers the cyanidation reaction in a bed of

Dramatic heap leach recovery and leach rate improvements were demonstrated in column leaching of South African gold ores also in 1988. Randol (1993) reported that Anglo American Corporation had demonstrated flotation recovery benefits of

Gold heap leaching Heap leaching is an industrial mining process to extract precious metals , copper , uranium , and other compounds from ore via a series of chemical reactions that absorb specific minerals and then re-separates them after their division from other earth materials.

18/06/2018 · Agglomeration for copper heap leaching Request PDF. Request PDF on ResearchGate Agglomeration for copper heap leaching Agglomeration of ore is a method which can be used to eliminate the migration of fi

Gold is dissolved by the cyanide and then removed from the heap or columns. It is then extracted from the pregnant leach solution by adsorption on carbon or resins. This cost-effective, proven method of ore extraction provides maximum recovery for many gold ores, …

13/08/2018 · Gold cyanidation (also known as the cyanide process or the MacArthur Forrest process) is a hydrometallurgical technique for extracting gold from low grade ore by converting the gold to a water soluble coordination complex.It is the most commonly used leaching process for gold extraction

Heap Leaching an overview ScienceDirect Topics

Estimated Water Requirements for Gold Heap-Leach Operations

First used on a large scale in the 1970s, cyanide heap leaching allows miners to extract microscopic gold flecks from low-grade ore. In a typical heap leach operation, vast quantities

The selective leaching of copper from a gold–copper

Kappes Cassiday & Associates 911metallurgist.com

This paper will combine three SME annual meeting presentations on reducing gold inventory in cyanide heap leaching. Information on Part I – Side slope leaching

On the optimization of heap leaching Multotec Home

REDUCTION OF GOLD INVENTORY IN CYANIDE HEAP LEACHING

SUMMARY Cyanide Heap Leaching Introduction Cyanide heap leaching is a process for recovering gold and silver by trickling cyanide solutions through low …

Improvements in Copper heap leaching by use of wetting agents

effect of crushing size on gold leaching rates BINQ Mining

Heap Leaching Gold Cyanide Scribd

processing of low grade gold ores by heap leaching is an important technological development. But a major drawback in heap leaching process is low recovery of the precious metals. The problems that generally lead to a low gold recovery and the possible solutions are discussed. INTRODUCTION Low grade gold deposits once considered uneconomic are now becom ing viable for two reasons: (1) the

heap leaching of copper perkinspreschool.com

SART for copper control in cyanide heap leaching – Copper-loaded carbon can also result in significant copper reporting to dorè bars along with gold and

Estimated Water Requirements for Gold Heap-Leach Operations

Heap Leaching of Gold-Bearing Deposits Theory and

Heap leaching is a process whereby precious metals such as gold and silver are extracted from rock by placing mineralized material on a lined pad (a base) in a

Heap Leaching Using Uncertainty and Global Sensitivity

Leaching reaction of gold with glycine–peroxide solution has been shown that it is a chemically controlled reaction (Oraby and Eksteen, 2014) for high concentrations (e.g. tank leach conditions).

THE ART OF HEAP LEACHING Lee JOHN Academia.edu

Application of SART to Heap Leaching of Gold-Copper

THE CYANIDE HEAP LEACHING BEHAVIOR OF CUPRIFEROUS GOLD

CHAPTER 5 Heap Leaching of Gold-Bearing Deposits: Theory and Operational Description James A. Brierley Introduction B iooxidation pretreatment of refractory precious metal ores and concentrates is

HEAP LEACHING OF Mindoro Resources Ltd

Heap leaching belongs to the group of percolation leaching processes and operates over ground. The procedure is illustrated in Figure 1.The oxide copper ore is piled up on leach pads, which have a slight slope of approx. 3° and a rubber lining, which seals the ground under the heap.

On the optimization of heap leaching Multotec Home

SART for copper control in cyanide heap leaching SciELO

The leaching and adsorption of gold using low

Leaching reaction of gold with glycine–peroxide solution has been shown that it is a chemically controlled reaction (Oraby and Eksteen, 2014) for high concentrations (e.g. tank leach conditions).

HEAP LEACHING GUIDE Hunter Industries

A MATHEMATICAL MODEL FOR ISOTHERMAL HEAP AND COLUMN LEACHING

Heap leaching is a conceptually simple process but has several characteristics that make modelling the flowsheet quite complicated. Fundamentally, it is a slow process.

Agglomeration-Heap Leaching Operations in the Precious

Gold is dissolved by the cyanide and then removed from the heap or columns. It is then extracted from the pregnant leach solution by adsorption on carbon or resins. This cost-effective, proven method of ore extraction provides maximum recovery for many gold ores, …

SART for copper control in cyanide heap leaching SciELO

The selective leaching of copper from a gold–copper

SART for copper control in cyanide heap leaching – Copper-loaded carbon can also result in significant copper reporting to dorè bars along with gold and

On the optimization of heap leaching ScienceDirect

Precious Metal Heap Leach Design and Practice Ore-Max

Day 51 Procedures to obtain gold Vat Leaching Process

Heap Leaching Heap Leaching is being done these days on relatively low-grade ores for gold, copper and uranium recovery. Typical operations take place for about one to three months per heap …

Real and Potential Metallurgical Benefits of HPGR in Hard

2006 IIR Conference Paper i Brian McNab EXPLORING HPGR TECHNOLOGY FOR HEAP LEACHING OF FRESH ROCK GOLD ORES Brian McNab Senior Metallurgist – Comminution

Excellent gold recoveries in Melrose heap leach

Leaching Mining Fundamentals

sgs minerals services. technical paper 2008-51 2008. application of the sart process to heap leaching of . gold-copper ores at maricunga, chile. kevan j. r. ford and robert d. henderson –– kinross gold corporation, and dr.

16 questions in Heap Leaching Science topic

STRONG FEASIBILITY STUDY RESULTS CONFIRM CASTLE HILL